Destil is our top product, with a concrete pressure up to 80kN/m2 , 100% compatible with Doka Framax ,is an innovative system for efficient concrete construction technology.

DESTIL offers increased efficiency and reduces costs through the following:

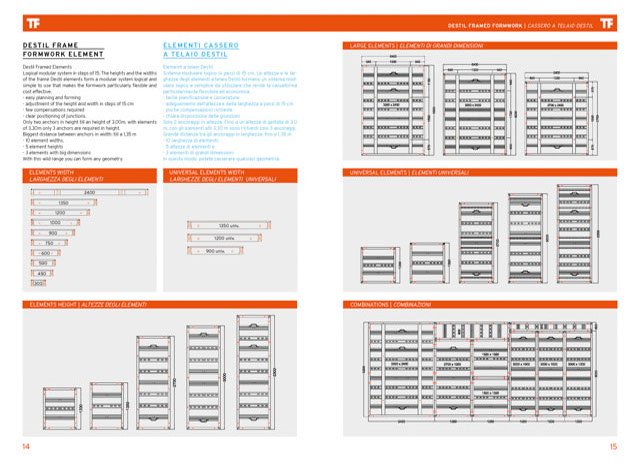

PANEL HIGHTS: available in heights of 330 cm, 300 cm, 270 cm, 135 cm, 120 cm. For each module height N.8 wide sizes are available (300/450/600/750/900/1000/1200/2400 cm). This means we have N.40 sizes in total, for the maximun flexibility and adaptability.

STEEL: highly resisting Steel, type S355MC Admissible load 80kN/m2. Thickness: 2.50 mm Finishing technique: Hot Zinc-coat A strong and quick system for heavy duty.

HIGH COMPATIBILITY with other formwork systems currently leader on the market.

NEW CONCRETE FINISHES: thanks to an innovative steel profile, we have improved visible concrete surfaces. Destil Formwork for Works of Art.

LONG LIFE: frames and profiles are hot deep galvanised both inside and outside.

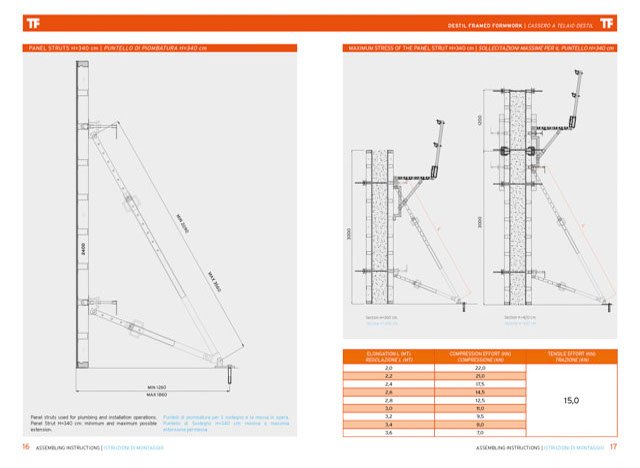

LOW DENSITY OF TIE RODS: only 2 tie rods are needed for concreting heights up to 330 cm panel.

LARGE-AREA CRANE OPERATION: versatile, quickly assembled and movable in large units. Destil is used on both small and large construction sites.

HIGH-QUALITY PLYWOOD: 18mm birch plywood with a 220 g/sqm phenolic coating or a plastic-coated plywood that lives 3 times longer.

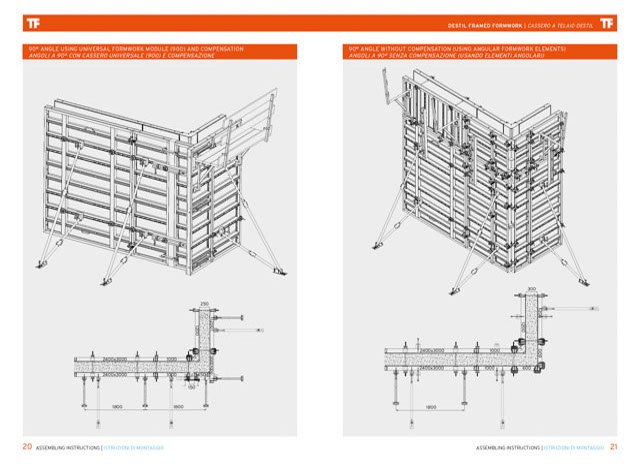

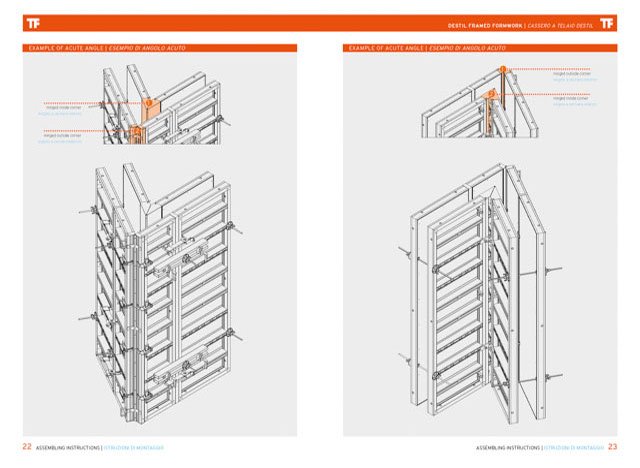

CONNECTIONS: singular geometry of steel profile allows the connection of different steel frame modules in any position by Quick-acting clamp and Multi-function clamp.

CORNERS AND CIRCULAR WALLS: all corners, articulated corners and panels for circular walls or columns are available.

TECHNICAL ASSISTENCE pre and post-selling.

ACCESSORIES: full range and interchangeability of all accessories.

SPEED: fast system for Walls, Columns and Slabs. Rapid planting, removing and moving on-site of the formworks.. The construction time is reduced by 25% compared to conventional methods.

REUTILIZATION: high number of possible reutilization (over 300). This steel frame system allows the construction of the following:

– Vertical formworks

– Horizontal formworks

– Formworks supported by shoring system

– Climbing formworks suitable for towers and bridge piers

– Dam formworks

– Formworks suitable for construction of elevator shaft

– Single-sided wall formworks

– Tunnel formworks